Background: Who SOCAR Is

SOCAR (State Oil Company of Azerbaijan Republic) is a major player in the global oil and gas industry, with a workforce of approximately 50,000 employees. Headquartered in Azerbaijan, SOCAR’s operations span the entire value chain of the oil and gas sector, including exploration, drilling, extraction, transportation, and more. Given the scale and complexity of their operations, SOCAR places a high priority on safety, efficiency, and continuous professional development, particularly in well control—a critical aspect of their drilling operations.

In addition to their core activities, SOCAR is committed to maintaining high standards across all areas of operation. The company holds several ISO certifications, including ISO 9001 (Quality Management), ISO 14001 (Environmental Management), and ISO 45001 (Occupational Health and Safety). These certifications underscore SOCAR’s dedication to implementing best practices and continually improving their processes to meet international standards.

Challenges: The Problems SOCAR Was Facing

Before partnering with 3t Drilling Systems, SOCAR faced significant challenges in ensuring their personnel were adequately trained in well control procedures. The training programmes they had in place were primarily locally developed and did not meet the international standards necessary for minimising risks in high-stakes environments like oil drilling. The existing training was not accredited by global organisations, such as the International Association of Drilling Contractors (IADC), which meant that SOCAR’s employees were potentially underprepared for critical well control scenarios.

Furthermore, without the use of advanced simulation technology, SOCAR’s training programmes lacked the hands-on, practical experience needed to effectively simulate real-world situations. This gap in training presented a risk not only to the safety of operations but also to the company’s reputation and compliance with international safety standards.

Solution: Why SOCAR Chose Simulation and 3t Drilling Systems

To address these challenges, SOCAR made the strategic decision to invest in advanced simulation technology for their well control training programmes. After evaluating various options, SOCAR selected 3t Drilling Systems as their supplier for several key reasons:

- Reputation and Experience: 3t Drilling Systems is renowned for their cutting-edge simulation technology and has a strong track record of enhancing well control training in the oil and gas industry.

- Customisation: 3t Drilling Systems offered SOCAR the ability to tailor the training programmes to meet specific operational needs, which was crucial for SOCAR given the unique challenges they face in both onshore and offshore environments.

- Accreditation and Standards: The simulators provided by 3t Drilling Systems are guaranteed to meet the rigorous standards set by the IADC, ensuring that SOCAR’s training programmes would be internationally recognised and respected.

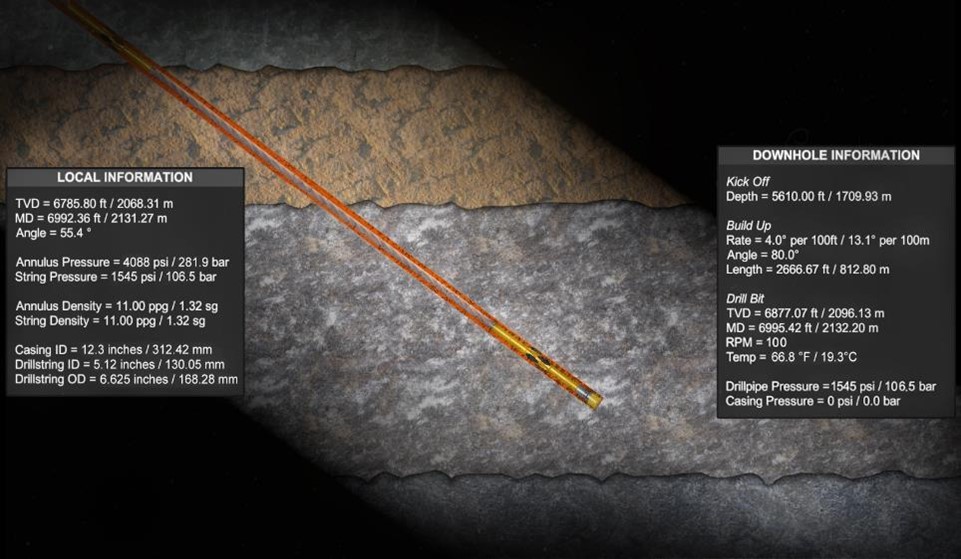

- Technology: SOCAR specifically chose a DrillSIM simulator, a state-of-the-art tool that replicates real-world drilling conditions with remarkable accuracy. The DrillSIM simulator allows trainees to experience and respond to well control scenarios in a controlled, risk-free environment, significantly enhancing their preparedness for actual field conditions.

- Expertise in Implementation: SOCAR was particularly impressed by the deep industry knowledge of 3t’s team, including Max Wyndham, Head of Business Development, who played a pivotal role in guiding SOCAR through the transition to a fully accredited training system.

Results: Current Situation and Future Outlook

Since implementing the DrillSIM simulator from 3t Drilling Systems, SOCAR has significantly upgraded its training capabilities. The in-house training programmes now include well control courses that are fully accredited by IADC, providing SOCAR personnel with the knowledge and skills needed to manage well control events effectively. The training is not only meeting but exceeding international standards, thanks to the extended course durations and the depth of content covered. This extension to the course is something SOCAR could only achieve from bringing the training course in-house.

The DrillSIM has become an integral part of SOCAR’s in-house training infrastructure. It enables instructors to simulate a wide range of scenarios, from routine operations to emergency situations, allowing trainees to develop critical thinking and decision-making skills. This enhanced in-house training capability and extended course duration has not only improved safety across SOCAR’s operations but also positioned the company as a leader in well control training in the region.

The feedback from SOCAR employees has been overwhelmingly positive, with many noting a substantial improvement in their understanding of well control procedures and their ability to apply this knowledge in real-world situations.

Looking ahead, SOCAR plans to expand its training programmes further by incorporating workover well control courses. This will allow SOCAR to continue leveraging 3t’s simulation technology to address more specialised training needs, ensuring their workforce remains at the forefront of industry standards. Moreover, SOCAR envisions using the DrillSIM simulator to develop customised training modules that address specific operational challenges unique to their onshore and offshore sites.

Quote from Max Wyndham, Head of Business Development at 3t Drilling Systems

“Partnering with SOCAR has been an incredible journey. Their commitment to safety and operational excellence is evident in every aspect of their training programmes. At 3t Drilling Systems, we are proud to have provided the simulation technology that is helping SOCAR set new benchmarks in well control training for the Caspian region. The success of this partnership is a testament to what can be achieved when cutting-edge technology meets a forward-thinking organisation.”

Conclusion

SOCAR’s collaboration with 3t Drilling Systems has not only resolved their previous training challenges but has also set the stage for continued innovation and excellence in well control training. With the successful implementation of the DrillSIM simulators and a robust in-house training curriculum that extends beyond the mandatory requirements, SOCAR is well-equipped to handle the demands of the oil and gas industry today and in the future. The partnership between SOCAR and 3t Drilling Systems is a prime example of how advanced technology and strategic collaboration can drive significant improvements in safety, efficiency, and operational excellence.